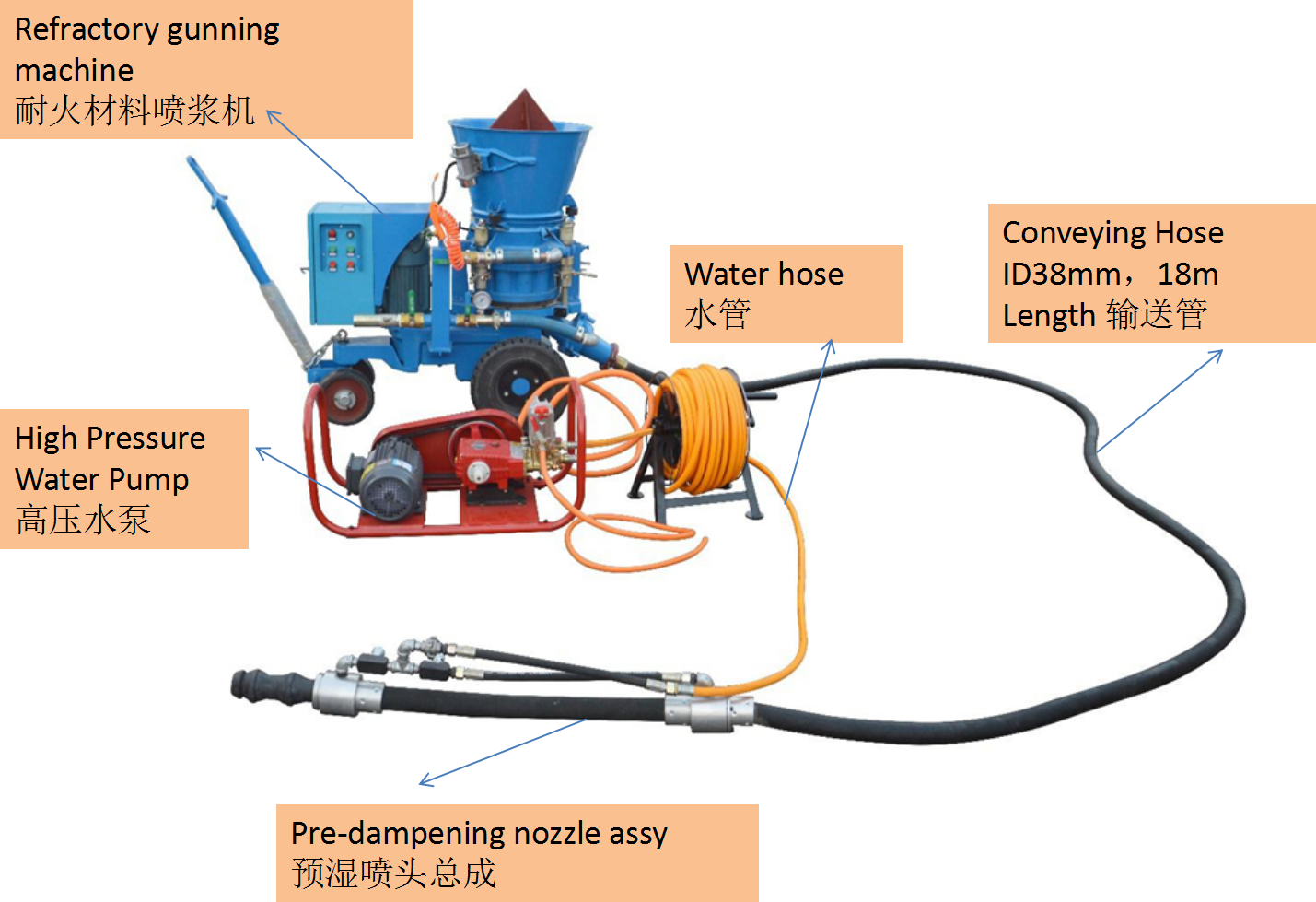

High pressure water pump is used for providing high pressure water for new type pre-dampening nozzle assy. There is one water ring in the nozzle assy, high pressure water go through water ring small hole and atomize. If so, water could be mixed even with materials, achieve best spraying effect. ABB frequency converter is used for adjusting motor speed, further control refractory gunite machine output from 1m3/h to 3m3/h. When the machine begin to work, small output could effectively avoid block because of larger output.